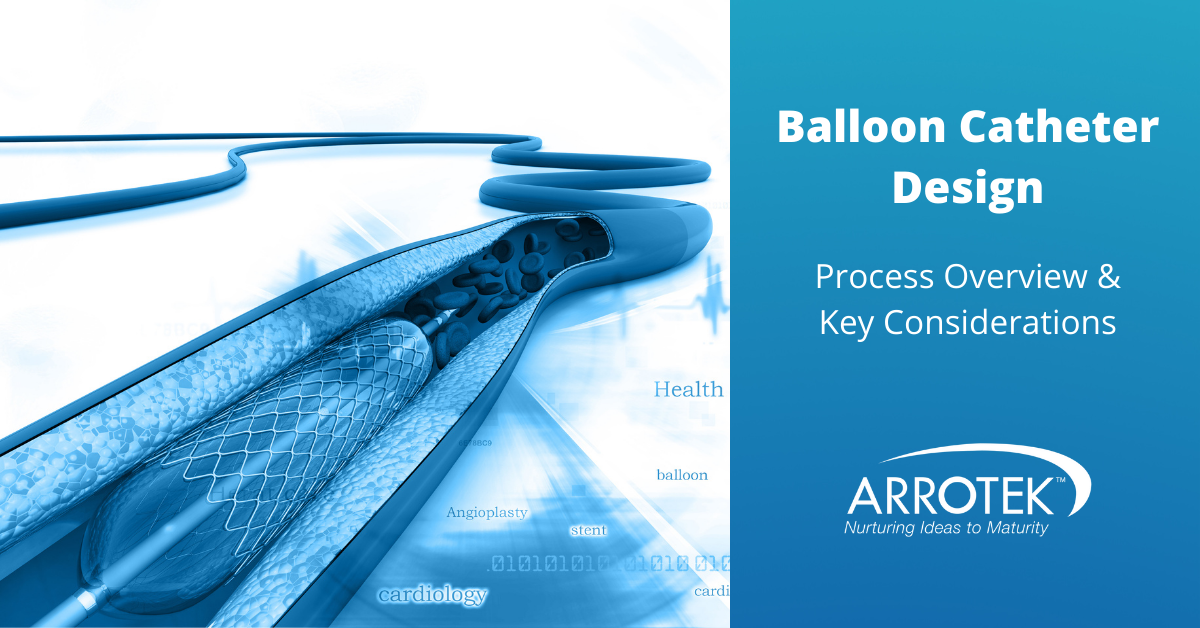

Balloon catheters are used for a range of medical procedures and applications, from delivering stents to opening blockages to dilating vessels to delivering therapeutics directly to a target location in the body. As a result, balloon catheters have transformed patient outcomes, particularly in complex procedures.

Balloon catheters have been used in healthcare for many years now, but the level of innovation in this area of minimally invasive medical devices continues at pace. Well-established balloon catheter applications are being enhanced, and new innovations are being developed.

From embedding electronics such as sensors and thermistors to developing balloon catheters that can access difficult-to-reach parts of the body, this is an area of medical device innovation that continues to push boundaries.

As with other advanced catheter technologies and minimally invasive medical devices, there are several factors to consider during the balloon catheter design process. This includes everything from the materials used in the manufacture of balloons to how the balloon integrates with the catheter to what the device will be used for.

Common Applications for Balloon Catheters

- Angioplasty applications that open blocked coronary arteries, including those that include innovative technologies, such as drug-coated balloons.

- Other dilatation applications

- Occlusion catheters for applications that include temporarily blocking vessels by redirecting or blocking the movement of fluids or objects.

- Stent delivery catheters

- Embolic protection applications, such as in carotid artery stenting procedures.

- Other implant delivery catheters, including catheters to deliver valves and grafts.

- Ablation catheters, including renal denervation, RF ablation, and cryoablation. Ablation applications typically involve the removal of biological tissue, such as in cardiac ablation surgery where tiny scars are created on the heart to maintain normal heart rhythms.

- Balloon septostomy catheters

- Heat transfer catheters

- Brachytherapy and intracavitary applications, including for brain cancer.

- Other drug delivery devices as balloon catheters are a highly effective alternative to intravenous therapeutic administration as balloon catheters deliver drugs precisely to the target location.

- Fallopian tube catheters for tuboplasty and other infertility treatments.

- Photodynamic therapy devices

- Laser balloon catheters

- Atherectomy catheters

- Anchoring and positioning applications, including urinary catheters.

- Valve sizing, delivery, and anchoring applications.

- Pumping applications, including to help the heart pump blood.

- Aspiration applications, including to remove thrombus from coronary and peripheral arteries.

- Tools for endoscopic procedures

- Diagnostic applications

- Sizing applications, including in angiographic procedures.

- Bone cement delivery, such as in vertebroplasty procedures.

Clinical Applications for Balloon Catheters

- Cardiovascular

- Structural Heart

- Electrophysiology

- Neurovascular

- Carotid

- ENT

- Endovascular Aneurysm Repair (EVAR)

- Gastrointestinal and oesophageal

- AV access and other venous applications

- Peripheral vascular

Types of Balloons

There are three main types of balloons used in balloon catheters:

- Non-compliant balloons – high-pressure balloons that have high strength characteristics so they can withstand the inflation pressures required to, for example, open a blockage by breaking up calcified lesions, or to dilate a vasculature.

- Semi-compliant balloons – for applications where medium-to-high pressures are required to enhance delivery and flexibility, such as in the pre-dilatation of lesions.

- Compliant balloons – low-pressure balloons that are inflated by volume instead of pressure. Compliant balloons conform to the lumen size / anatomy to, for example, form a seal in occlusion applications.

Common Balloon Materials

Selecting the right material for the balloon is a crucial part of the balloon catheter design process. Essential considerations include:

- Lubricity

- Tensile strength

- Compressibility (for inflation/deflation optimisation)

- Burst pressure performance

- Expansion ratios

- Concentricity

- Wall thickness

- Inflation by volume capabilities

- Biocompatibility

- Hemocompatibility

- How easy it is to withdraw the balloon into the catheter

Commonly used balloon materials include:

- Polyurethane

- Nylon

- Polyethylene (PE)

- Polyethylene terephthalate (PET)

- Polyolefin copolymer (POC)

Integration with the Catheter

Another important part of the design process is optimising the integration of the balloon with the catheter. Various types of catheters are used to create a balloon catheter device, including over-the-wire catheters, rapid exchange catheters, fixed wire catheters, and more.

Catheter Performance Requirements

In addition to the performance requirements of the balloon, there will also be catheter performance requirements that must be considered during the balloon catheter design process.

There are many different factors to consider in catheter design, but those that are highly specific to balloon catheters include:

- Ability to minimise balloon inflation and deflation time

- Trackability to optimise the navigation of the catheter through the body, including through tortuous vasculatures

- Minimising the insertion profile of the catheter to improve patient recovery

Balloon Catheter Design Expertise

At Arrotek, we have extensive experience in catheter design, as well as the design and development of balloon components for balloon catheter devices. As a result, we can provide a complete balloon catheter design service that includes everything from early-stage concept development through to Stage 2 prototype production and beyond into the regulatory, manufacturing, and commercialisation phases.

If you have a query about balloon catheter design, or to discuss your idea for a new medical device in the strictest confidence, please complete the form below and a member of our engineering team will get back to you.